Well, this project happened because of lazy chicken... That go eat, sometimes to the shopping mall, for a walk, and the eggs lay in the cold, so something had to be done!

So, the purpose of this project is to make possible to reproduce birds (in this case chickens) without the presence of the mother.

So, the purpose of this project is to make possible to reproduce birds (in this case chickens) without the presence of the mother.

I started by building a wooden box, and isolated with silicon, then used the guide to build the

power source, drilled some holes to connect the interior to the outside. At this point I had a PSU and a box, needed something to warm the box, an halogen lamp would be perfect, so got a connector and a zinc tube in the hardware store, what happens here is that the lamp warms the tube, and dissipates heat, not burning the box.

Added a computer fan (that can not be seen in the up picture) like the one on the left, that works inside the tube creating an air flow making the temperature equal all over the box. This item is needed to spread the hot-air within the box, otherwise we would have a very hot area near the lamp and a not so hot, (even fresh during winter) area in the more far point from the lamp. The fan is connected to the +12V/gnd and starts when the PSU is ON, does not have an on/off button, no need.

First tests failed, after one hour of heating the outside of the box would be warm, and the inside not in the proper temperature, so isolating was needed, used then some roofmate isolating boards, worked perfectly, less heating time, more time within the correct temperature without heating (37 degrees celsius).

To the electronic bench now!

After some research I found out that the eggs should be heated to 37/37,5 celcius degrees during approximately 21 days, during this period they should be turned twice a day, and more often on the 3 final days, a wet sponge must be inside the box to soften the egg shell, during the final period this sponge should be wetter.

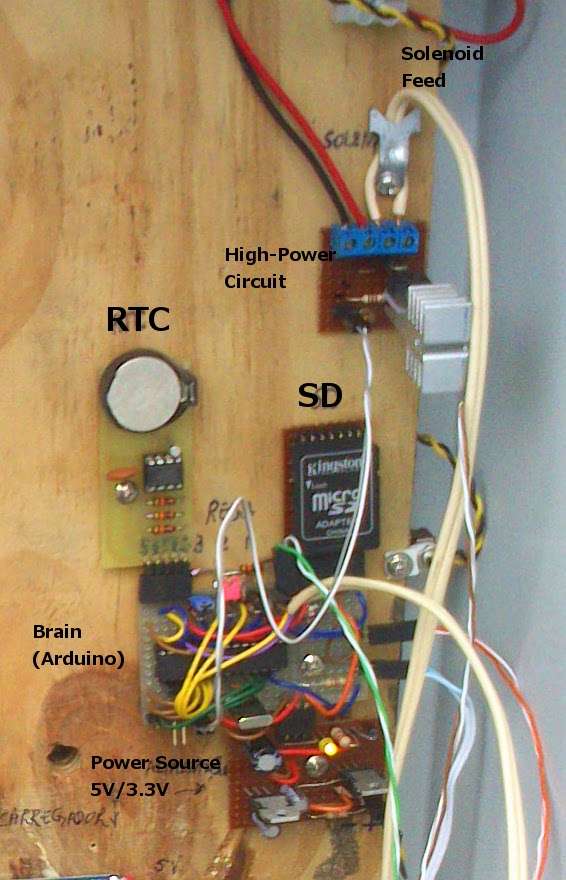

Now for the electronics, I connected an arduino board as you can see on the right, with the LM35DZ inside my box, covering the temperature, and two LED's one to inform the heating on (the yellow, digital output #3) and other to tell me that heating is off (green LED, digital output #4) but the system is alive. The digital #5 is the output to set the relay on/off, using the

relay shield built before, where you see "digital port 13", connect the digital #5 as referred previously.

As power source for the relay shield, you should use the +12V/gnd from the PSU, and the same for the arduino, you just have to solder two wires to a proper jack, (like the one in the right) remembering that the +12V go inside and the gnd on the outside. Arduino and relay shield MUST share the gnd, (common ground) otherwise the shield will not work.

On the left there is a picture of the final result, the temperature sensor on the right bottom of the picture, with a green surrounding, far from the lamp, within the egg area. The green arrow shows the air-flow from the fan that stands behind the lamp, distributing the hot-air in the box.

Now with all the hardware set, we need the software, and that, lays

here, feel free to change it within the license authorization. Basically you set it on, it starts regarding the temperature indicator, if less than 37 degrees, sets the yellow LED and relay ON for heating purposes, when reaches a comfortable temperature, sets the relay OFF and the green LED ON, and stays controlling the temperature, and the behavior goes on and on, until the birds hatched!

I can tell you the system works fine, and as a final note I leave you the console output.

Materials used:

- Wooden box

- Roofmate isolator

- Arduino

- Old PC fan

- Homemade relay shield (see

link)

- Customized PC power source (see

link)

- 50W halogen lamp and connector

- Zinc pipe/tube

- Green LED

- Yellow LED

- Power jack

- LM35dz

- Wires, connectors, etc.

Feel free to contact me.

On the left, is a picture of the homemade probe which measures the moist in the soil, the pic was taken a couple weeks ago and the berries are quite bigger now. I must say that the dry-up problem they had last year no longer happens!

On the left, is a picture of the homemade probe which measures the moist in the soil, the pic was taken a couple weeks ago and the berries are quite bigger now. I must say that the dry-up problem they had last year no longer happens!

.jpg)